Tag

Tag

We provide Lockout Tagout (LOTO) solutions designed for maximum safety in energy isolation. We develop systems that protect your employees, keep your production processes uninterrupted, and fully comply with international standards.

Emre Bulut

Emre Bulut

"Thanks to Technic Safety's LOTO solutions, our energy isolation processes have become safe. A professional and reliable team!"

Technic Safety was founded with the belief that no production process is safe unless energy is controlled. Our innovative lockout/tagout solutions prevent workplace accidents and ensure people can work safely.

With the solutions we have developed in energy insulation processes, the accident rate has been reduced to 0% in all businesses we have advised to date.

Customer Satisfaction

Projects Secured

Our Lockout/Tagout solutions developed to ensure worker safety during maintenance, repair, and cleaning of industrial machines prevent the uncontrolled release of energy and reduce workplace accidents to zero. With our locking and tagging equipment compliant with international standards, we ensure maximum safety in production processes.

To ensure maximum safety in energy isolation processes, we make your employees competent with LOTO training and consultancy services provided by our expert team. Through risk analysis, legal compliance and on-site applications, we bring a safety culture to your business and help prevent workplace accidents.

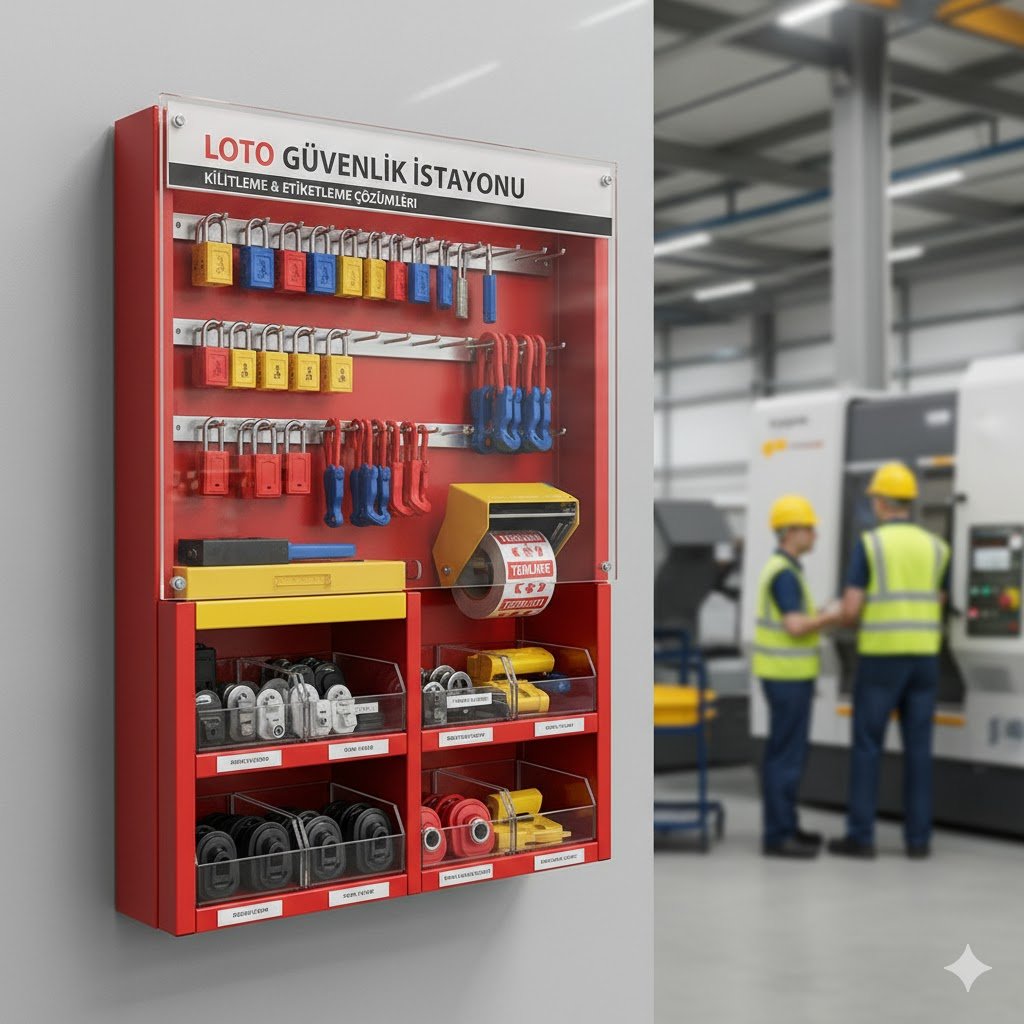

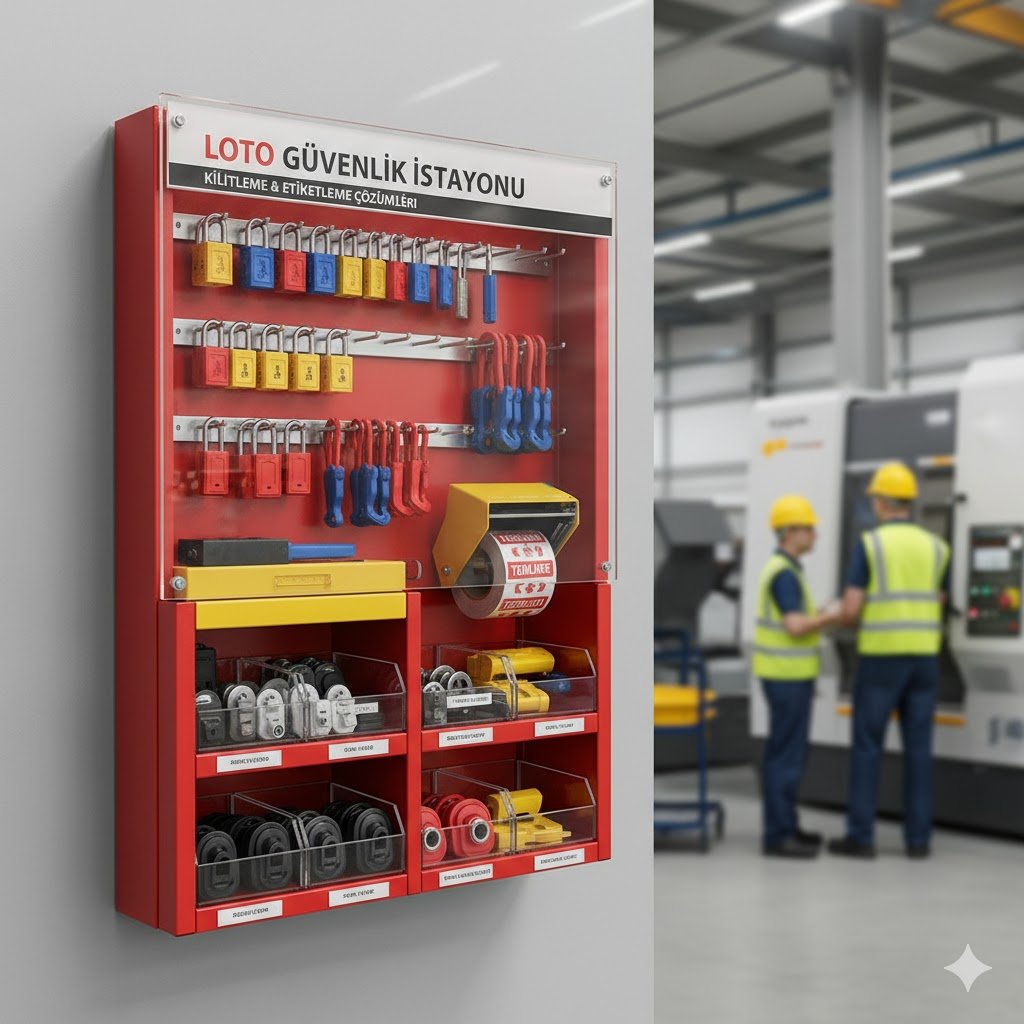

Our industrial safety stations ensure LOTO equipment is stored regularly, accessible and safely, increasing efficiency and facilitating safety processes in the workplace. With durable construction, modular design and high-performance materials, they provide long-lasting solutions for your business.

Designed for safe storage of chemical liquids and control of possible spills in industrial facilities, our spill pallets minimize environmental risks. With durable material structure and high load capacity, they create safe working areas and support environmentally friendly production processes.

The first step of the LOTO process is to correctly identify all energy sources and potential hazards in the facility. Energy sources such as electrical, mechanical, hydraulic, pneumatic or chemical energy are analyzed to identify elements that could endanger worker safety. A detailed risk assessment at this stage forms a solid foundation for the effectiveness and safety of subsequent steps.

In this step, the identified energy sources are isolated using appropriate lockout devices. We select padlocks, valve and plug locks, cable sets, pneumatic locks, tags and station solutions according to the type of energy and field conditions to ensure safe isolation.

After locking, each device or energy source is clearly labeled to indicate the lockout status. Tags provide critical information about the lockout process and notify all employees that maintenance or service is being performed. This step ensures that no one removes the locks or restores energy inadvertently.

In the final step, lockout and isolation applications are inspected and tested. Only after verifying that all equipment is safely installed and necessary precautions are taken is the system re-energized. This ensures that a safe working environment is consistently maintained.

Average Rating

After working with Technic Safety, our energy isolation processes have completely changed. Thanks to their LOTO solutions, we ensure maximum safety during maintenance and repair.

Factory Manager

They brought not only equipment but also a culture of safety to our company. Now all our employees are much more aware of energy isolation processes.

Production Director

We solved all the complexity we experienced in energy isolation processes with Technic Safety solutions. Thanks to site analysis, training, and consulting support, we increased our production efficiency and prevented workplace accidents. With their professional and safety-focused approach, they were by our side every step of the way.

Operasyon Yöneticisi

They brought our LOTO processes up to global standards with corporate support, consulting, and implementation services.

Operations Manager

After starting to work with Technic Safety, we completely eliminated safety risks in maintenance and repair processes. LOTO solutions were integrated into our business not only as equipment but as a safety culture. Our employees are now much more aware and work more safely when it comes to energy isolation.

Occupational Safety Manager

Thanks to LOTO training and field applications, our workplace accidents have decreased by 90%. Technic Safety's safety-focused approach has added significant value to our business.

Occupational Safety and Health Specialist

@ 2025 Copyright - lockout.com.tr

Technic Safety